IRON MINING: WHERE AND WHY?

It was called the barren waste, this land that is now Michigan’s

Upper Peninsula. However, since its first iron ore shipment of two hundred pounds in 1846,

the Upper Peninsula mines (below) have produced well over one billion tons of iron ore.

Some barren waste!

Iron ore is Michigan’s most valuable non-fuel, mined commodity. In

1994, the Lake Superior area produced 95% of the US’s supply of iron ore. Minnesota

leads the nation with 70% of the production, while Michigan produces most of the rest

(25%). More than 98% of the iron ore that is shipped in the world is used to make steel,

while the rest is used in pigments, chemicals, or in other, minor uses. Natural ores were

the primary type of ores mined prior to World War II.

In the early 19th century, settlers moving westward from the eastern

United States bypassed the UP because of its reputation as an inhospitable wilderness.

However, favorable attention was drawn to the region by Douglass Houghton’s 1841

geological report describing the presence of copper on the Keweenaw Peninsula. Adding to

this excitement was the publicity surrounding the delivery of a two ton Ontonagon copper

boulder to Detroit in 1843.

During the first part of the Precambrian era, a 250 million year-period

of quiet, which we name the Huronian from its record north of Lake Huron, thick sediments

were laid down in a shallow sea trough that covered the Lake Superior region. In places

thick sand was deposited; in other fine muds, and in other places pure lime, accumulated

in the shallow but slowly deepening sea. Over the sand great masses of iron minerals

accumulated, either by chemical action or by the work of iron forming bacteria, or by both

and perhaps other means, until vast thicknesses of sand and iron sediments were built up,

and the world’s largest iron deposit was in the making in Minnesota, Wisconsin, and

Michigan. In that far ago time the foundations of Michigan’s wealth and the

automobile industry were laid in the old Huronian sediments we now find in the iron ranges

of Marquette, Baraga, Iron, Dickinson, Menominee, and Gogebic counties.

Huronian (Early Proterozoic) rocks hold the vast wealth of the

iron formations in Michigan. As we have found, those rocks are broken, faulted, some even

turned over backward. They are so cracked and shoved about, that the edges of ore bodies

are separated by hundreds of feet, which makes mining difficult and the search for ore

bodies complicated. But since its discovery in 1844 Michigan has mined one of the richest

iron ore fields in the world, and for more than 100 years the wealth and industry of the

state has depended in large measure on iron ore.

The term "iron-formation" is perhaps the most enigmatic and

controversial term ever concocted for a rock type. Iron formations were deposited in many

parts of the world during the Early Proterozoic (Precambrian) in formations that are 500

to 2,000 feet or more thick and that extend for hundreds of miles. Therefore, thousands of

cubic miles of iron-rich sediments were deposited in a number of basins. After the Early

Proterozoic (about two BILLION years ago) deposition of iron-formation ceased, and this

distinctive rock type is essentially absent from younger geological sequences.

Thus, we are left to puzzle over where the vast quantities of iron came

from during the Early Proterozoic, and why iron is not found in younger rocks. This all

suggests that a major change in the chemistry of the surface environment of the

earth must have occurred around two billion years ago to prevent iron-formation deposition

in younger rocks. Most geologists now believe that the major change was the development of

an oxygen-bearing atmosphere on earth. Iron is relatively soluble in an

oxygen-deficient environment (like that of the earliest Precambrian) and therefore would

be present in large amounts in ocean waters. In oxygen-rich environments, like the present

atmosphere, iron is incredibly insoluble, and therefore is not present in quantity in

ocean waters.

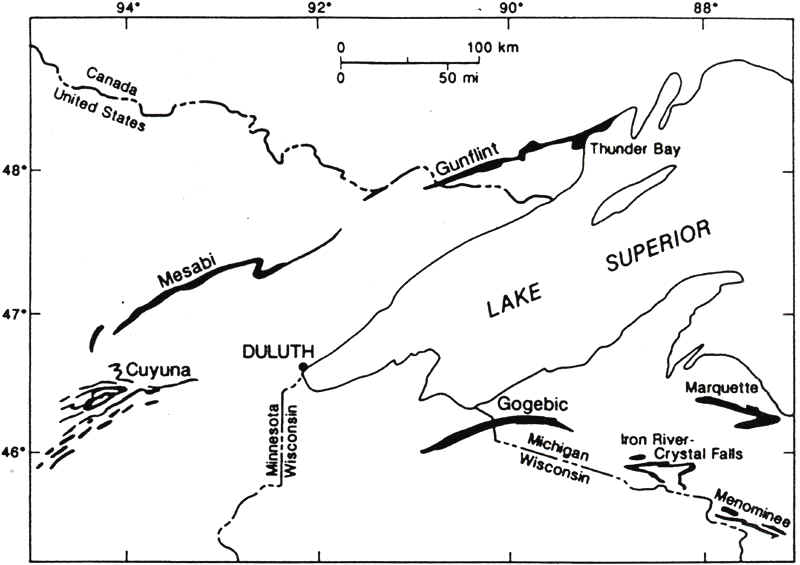

Iron-formations have played an important part in the settlement and

economic development of the Lake Superior region, for these rocks are the source and host

for a vast majority of the iron ore produced in North America. The map below shows

that iron formations are commonplace throughout the Lake Superior region. The

largest of these is the Mesabi Range in Minnesota.

Source: Unknown

And today, land devoted to mining in the Great Lakes region is dominated by the large,

open-pit mines in the Mesabi Range of Minnesota.

Source: Unknown

Iron ore was first "discovered" by European settlers when the

early land surveyor, William Austin Burt, was shown iron ore by an Indian chieftain near

what is now Negaunee, Michigan, in 1844. He had noticed a strange movement of his compass

needle while surveying near where the present town of Ishpeming is located.

Mining commenced in 1846, grew steadily, and has continued to the

present time. Discovery of iron ore in other parts of the Lake Superior region constitutes

one of the most colorful chapters in the history of the Great Lakes area. Mining was

second only to logging in bringing in new people and in opening the area to settlement.

Its importance, however, has far outlasted that of logging, for it is still a major

contributor to the economy of the region.

The iron ores were found in near surface zones of enrichment

in Precambrian rocks of the northern Great Lakes states. At the peak of WW II, 103 natural

ore mines were functioning in Minnesota and 43 were running in Michigan. These ores

averaged about 60% iron. They could be shipped directly to the steel mills without

"beneficiation" (the process of crushing, screening, drying, washing, and other

processes that separate the ore particles from the worthless silica that is intimately

intermingled with it in low-grade ores).

Iron-formation was first studied in the Lake Superior region in the

late 1800's. In fact, iron-formations in this region are the "standard" to

which others throughout the world are compared. Although Michigan has many iron-rich

rocks, usually the amount of iron in them is so low as to preclude mining. In iron

formations, the amount of iron has been concentrated by weathering and leaching of

non-iron minerals, such that we only use the term "iron formation" for rocks

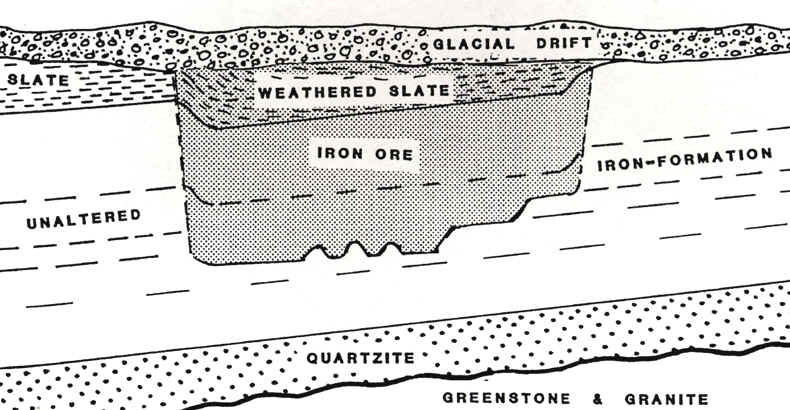

that contain >50% iron. The ore (iron) is concentrated by downward percolating

water, and occurs in places where downward flowing waters are guided and converge, such as

along a slanting layer of impermeable rock below. Along these channels silica is

removed and iron oxides are concentrated. Leaching is more efficient in places where

the original sedimentary rock (containing thin layers of iron-rich materials) are bent,

folded and broken, acting like a sieve and not a barrier to infiltrating water. The

diagram below illustrates the relationship between unaltered "iron formations"

and the weathered, leached iron ore, as they are found in the many iron ranges of the UP

and Minnesota.

Source: Unknown

This time of iron formation occurred in the long interval between the Jurassic (about 200

million years ago) and today. During this time, few rocks were actually forming in

Michigan. Instead, all the forces of erosion were at work creating much of our

scenery, exposing our mineral wealth, and creating some of it. The old Precambrian area

west of Marquette was eroded most rapidly. The edges of the Cambrian sandstones were worn

away off the old granites and Huronian iron formations, leaving only small caps of

sandstone to show where the Cambrian seas had been. The iron formations were not ores when

first exposed, but during the long ages of their exposure surface waters leached out other

minerals leaving the iron behind, gradually changing the upper few hundred feet iron ore,

or what the miners called "direct shipping ore". That explains in part why the

upper parts of the iron formations are rich and the lower levels lean in iron.

Although iron-formation has a simple composition---it is composed of

chert (biochemically precipitated quartz) and iron minerals---it is extremely variable in

appearance. Both the chert and iron minerals are varied in color. Despite these

variations, iron-formations have distinctive features that provide a basis for

identification. As the name implies, they are rich in iron minerals, with one or more

iron-bearing minerals constituting nearly half of the volume of the rock. Iron

formations are thinly-banded and are of chemical-sedimentary origin.

Source: Unknown

Iron-formations form distinctive sedimentary rocks in greenstone

belts in Archean-age rocks. Iron-formations consist mainly of chert (chemically

precipitated quartz) and iron-rich minerals. In some units the rock may be mainly

chert; in other it may be chert-hematite or it may be jasper-hematite, which is a

spectacular rock with alternating red and gray layers, each about 5-20 mm thick. Chert and

magnetite are by far the most common minerals in the iron-formations. Other iron minerals

include siderite and hematite. The image below shows a few specimens of iron

ore--iron formation. The gray metallic ore is magnetite, while the red ore is

hematite. The round thing in the middle is a quarter.

Source: Photograph by Randy Schaetzl, Professor of Geography - Michigan State University

Some iron-formations seem to have formed by volcanic hot springs

contributing iron and silica to sea water, probably in basins between volcanic islands.

The silica and iron was probably precipitated by biochemical processes.

Some iron-formations have highly carbonaceous layers (now mainly

graphite) associated with them. Indeed, carbonaceous shales and graphitic layers are

common in both the sedimentary and volcanic rocks of greenstone belts. Studies of

these carbonaceous layers indicate that they are composed mainly of organic carbon.

This would attest to the presence of primitive organisms (probably blue-green algae and

bacteria) in amounts great enough to accumulate in layers many feet thick in the waters in

which the greenstone belts formed. It also points to the antiquity of life on earth, for

the oldest greenstone belts yet studied (at least 3,300 million years old in South Africa)

have evidence that primitive life was abundant enough to leave a record.

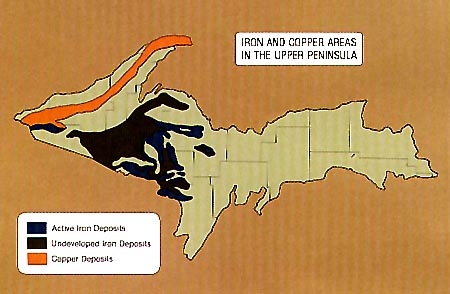

Iron was located in three of four areas in the Precambrian rocks of the

western UP. The map below outlines the locations of Michigan's major iron ranges.

These iron ranges are the roots of middle Precambrian mountains.

Of the six principal iron ranges, or areas, in the United States, three are

located primarily in Michigan: the Marquette Range, all of which is found within the

state, and the Menominee and Gogebic ranges which are located in both Michigan and

Wisconsin. Approximately 40 miles long and 3-10 miles wide, the Marquette Range

stretches across the UP from the city of Marquette to a few miles south of L'Anse on the

Keweenaw Bay. The Gogebic Range lies partly in Michigan and partly in Wisconsin. It is

divided by the Montreal River, a short stream that flows into Lake Superior about 25 miles

east of Ashland, WI. This range extends almost 80 miles between Atkins Lake in Wisconsin

and Lake Gogebic in Michigan; the Michigan section is approximately 25 miles long and

stretches from the state boundary at Ironwood to a point slightly west of Lake Gogebic.

The greater portion of the Menominee Range lies in the state of Michigan and includes the

towns of Iron Mountain, Norway, and Vulcan. Main iron deposits in this range extend in an

east and west direction, north of Iron Mountain.

If iron and steel manufacturing happened to be localized by its ore

sources rather than by coal sources or markets, suffice it to say that the economic

development and history of the Upper Peninsula would have been much different than it is.

At first the iron ore was smelted in charcoal furnaces near

Marquette---one of the old furnaces is now a tourist exhibit. The charcoal was made from

the "inexhaustible" hardwoods of the original forest, but as the hardwoods were

depleted and newer methods of smelting came into use it became cheaper and more expedient

to move the iron ore to the fuel---the coal of Pennsylvania. A few furnace towns were

abandoned and their buildings left to crumble and stare blankly at the brush growing in

the streets.

The Marquette Range

First to be discovered, the Marquette Range had been of interest to geologists

since the early 1840s when Douglass Houghton, Michigan's first State Geologist, conducted

a systematic scientific analysis and exploration of Michigan's Upper Peninsula. He

published his findings in a lengthy report, detailing the locations of minerals in the

Lake Superior area. Although he was not aware of the quantity of iron ore deposits in the

area, Houghton did state that iron deposits were to be found on or near the south shore of

the lake. Houghton's findings were substantiated and enlarged by the activities of William

A. Burt, a United States Deputy Surveyor. Burt, in attempting to establish the east-west

line between townships 47 North and 48 North, approximately one mile south of Teal Lake,

noted strange variations in his magnetic compass needle. When using Burt's own invention,

the solar compass, no variations were observed. Searching for the cause of this

disturbance, the surveying party discovered deposits of iron ore, or hematite. In 1845,

the search for iron ore began in earnest, and the first major discovery was made near the

present site of Negaunee. The men of the search party formed the Jackson Mining Company on

July 23, 1845, and iron mining in Michigan officially began. A producing wrought iron from

ore was erected on Carp River, and it was there that the first metallic iron was made.

The first blast furnace, built near the Jackson Mine, went into operation in April

of 1849.

The Civil War increased the need for Lake Superior iron, and the volume

of shipment began a steady increase, with additional mines opening on the range. In 1861,

the output for the Marquette Range was 120,000 tons; by 1868, annual figures had reached a

half million tons; and, by 1873, the range produced over one million tons of ore, a figure

that steadily increased through the turn of the century.

Source: Unknown

The Menominee Range

Before the Civil War, the major iron-producing region was the Marquette Range, but the

postwar discovery of iron in the Menominee and Gogebic ranges greatly expanded

Michigan’s production capacity.

In 1846, William A. Burt, in the process of his linear land survey,

noted signs of iron ore in the Crystal Falls area. In May of 1849, J. W. Foster was sent

by Dr. Charles T. Jackson to investigate the reports of iron ore on the Menominee River,

and Foster's subsequent report listed large beds of specular ore in Section 30, T40N,

R30W, near Lake Antoine. In 1866, Thomas and Bartley Breen, timber speculators from

Menominee, located iron deposits near present Waucedah, Michigan. Although the Breen

brothers had discovered what later became the very profitable Breen Mine, actual mining

operations on this location did not commence until 1870. In 1878 five mines were

actively engaged in shipping from the Menominee Range: the Breen, Cyclops, Norway,

Quinnesec, and the Vulcan.

With the 1855 completion of the Soo Locks, the early lakeside mines

were able to easily transport the bulky ore to smelting sites and markets, but as

operations moved inland, the need for reliable, efficient, internal improvements became

apparent. Railroads seemed to provide the solution. Construction began in the late 1850s,

and the first interpeninsular line was completed in 1881.

Production reached its peak in 1920 when it shipped almost seven

million tons of iron ore. Decline began in the 1930s, and today crumbling ruins are almost

all that remain of most of the Menominee mines, once bustling centers of activity and

production.

Source: Unknown

The Gogebic Range

The first official recorded notice of the presence of iron ore on the Gogebic Range was

included in the 1848 report of Dr. A. Randall, who saw exposures of iron ore approximately

halfway between Hurley and Mellen, in Wisconsin. Attention was drawn in Michigan to the

possibilities of the Gogebic Range by the report of the Geological Survey for the State of

Michigan. Professor Raphael Pumpelly and Major T. B. Brooks traced the iron formation

across the Montreal River into Michigan and, in later years, mapped the range extending

eastward toward Lake Gogebic. Official credit for the discovery of iron is given to

Richard Langford, a trapper and hunter, who claimed to have seen red ore outcropping from

the roots of an overturned tree south of the present city of Bessemer in 1879 or 1880.

By 1884, this location, known as the Colby Mine, began to produce commercial iron

ore. The early explorers and prospectors on the Gogebic Range experienced the

particular hardships of a land devoid of roads or even passable trails. Supplies had to be

packed overland from Ontonagon or were brought by boat from Ontonagon to Ashland to the

mouths of the Montreal and Black rivers. However, soon after the opening of the range

for mining, the railroad made its initial entrance. The first ore from the range

came out of the Colby, and 1,022 tons were loaded onto flat cars in October of 1884, sent

to Milwaukee, and then transshipped by barge to Erie, Pennsylvania. By 1910, three

separate railway lines served the Gogebic Range, and approximately four million tons of

iron ore were being shipped annually. From 1893 through the first decade of the 20th

century, production levels ranged from 3-4 million tons of ore, and the Gogebic continued

to be a productive iron range.

The region near Ishpeming, in the heart of the Marquette Iron Range, was chosen during the mid-20th century because trees do not block the view of the iron-rich hills. Today, regrowth of forest has occurred. The hills are composed of iron-rich rocks like diorite, and other "iron formations".

We celebrate the 1844 discovery of Michigan’s iron ore

deposits, but we should really think of it as the "final" or

"commercial" or "official" discovery of this resource. For thousands

of years before the European discovery of North America, the continent’s prehistoric

inhabitants knew of and made use of native metals and metallic ores. It is ironic that the

American discoverers of what became the Jackson Mine (near present-day Negaunee) were led

to the site by a local Native American. The technologies Native Americans employed and the

resulting products were vastly different from those the Europeans would introduce.

Industrial-scale usage of metals never took place during the prehistoric period. However,

metals held special significance in the spiritual and ritual lives of Native Americans

that did not exist in the Euro-American world.

Using a combination of the traditional techniques of cold-hammering,

annealing (reheating), riveting or abrasion, Native Americans were able to craft metal

artifacts of remarkable ingenuity-and often of great beauty-from gold, silver, copper and

galena. Their use of iron is probably not so well known. Iron is one of the most common

elements in our environment and ourselves. It is the "hemo" in the hemoglobin of

our blood. However, it rarely occurs in a pure, or native, state. Nevertheless,

prehistoric people made use of iron in its many impure forms.

Taconite, a common form of iron chemically bound with silica, was

chipped and flaked into projectile points. Marcasite, or iron pyrite, was ground into

cones and hemispheres. Hematite, the richest ore source for most of the iron mined on the

American continent, was pecked and ground into celts, axes, cones and plummets. Just as

often, Native Americans were searching for the brilliant red oxide, a ready source of

pigment. An unlikely source of iron used prehistorically was meteorites. Decorative items

such as earspools, beads and buttons, as well as small chisels shaped like the incisors of

beavers found in Ohio burial mounds, were pounded out of meteoric iron brought from

Kansas.

True metallurgy and the reduction of ores to pure metals or alloys

required a level of technology not reached in pre-Columbian North America. Most

prehistoric cultures were capable of generating temperatures high enough to melt lead and

occasionally copper but never iron.

Click here to continue on with part two this page. There's a lot more!

Some of the images and text on this page were taken from various issues of Michigan History magazine.

This material has been compiled for educational use only, and

may not be reproduced without permission. One copy may be printed for personal

use. Please contact Randall Schaetzl (soils@msu.edu)

for more information or permissions.